Types of Screws for Cabinet Face Frames

When constructing cabinet face frames, selecting the right screws is crucial for ensuring a sturdy and long-lasting build. There are several types of screws commonly used for this purpose, each with its own advantages and disadvantages. Let’s delve into the characteristics of each type to help you make the best choice for your project.

Wood Screws

Wood screws are a popular choice for cabinet face frames due to their versatility and strong holding power. They are designed to be driven into wood, creating a thread that securely holds the pieces together.

Wood screws come in various sizes and materials, including:

- Size: The size of a wood screw is measured by its length and diameter. Common sizes for cabinet face frames range from 1-1/2 inches to 2-1/2 inches in length and #8 or #10 in diameter.

- Material: Wood screws are typically made from steel, brass, or stainless steel. Steel screws are the most common and affordable, while brass and stainless steel offer greater resistance to corrosion.

Advantages of Wood Screws:

- Strong holding power: The threaded design provides excellent grip and prevents the screws from loosening over time.

- Ease of installation: Wood screws are relatively easy to drive into wood, especially with a power drill.

- Available in various sizes and materials: This allows for customization based on the specific needs of the project.

Disadvantages of Wood Screws:

- Prone to stripping: If the screw is overtightened or the wood is too hard, the screw head can strip, making it difficult to remove.

- May require pre-drilling: Depending on the wood type and screw size, pre-drilling may be necessary to prevent splitting.

- Appearance: The screw heads can be visible, which may not be aesthetically pleasing in some applications.

Examples of Wood Screw Brands:

- GRK Fasteners: Known for their high-quality, self-tapping screws with excellent holding power.

- Spax: Offers a wide range of wood screws in various sizes and materials, including stainless steel and brass.

- Simpson Strong-Tie: Provides a variety of wood screws designed for specific applications, including cabinet construction.

Drywall Screws

Drywall screws are designed for attaching drywall to studs or joists. While not traditionally used for cabinet face frames, they can be a viable option in certain situations, such as attaching the face frame to drywall directly.

Advantages of Drywall Screws:

- Cost-effective: Drywall screws are typically less expensive than wood screws.

- Easy to install: They are designed to be driven quickly and efficiently using a drill.

Disadvantages of Drywall Screws:

- Limited holding power: Drywall screws are not as strong as wood screws and may not be suitable for heavy-duty applications.

- May not be compatible with all wood types: Drywall screws are designed for drywall and may not provide adequate grip in harder woods.

- Appearance: The screw heads are typically larger and more visible than wood screws, which may not be desirable in some applications.

Examples of Drywall Screw Brands:

- GRK Fasteners: Offers a variety of drywall screws with different lengths and finishes.

- Spax: Provides drywall screws with a unique self-tapping design for easy installation.

- Simpson Strong-Tie: Produces drywall screws specifically designed for attaching drywall to studs.

Cabinet Screws, Best screws for cabinet face frames

Cabinet screws are specifically designed for use in cabinet construction. They are typically made from steel or stainless steel and feature a unique design that provides strong holding power and prevents loosening.

Advantages of Cabinet Screws:

- Strong holding power: Cabinet screws are designed to provide maximum grip and resist loosening over time.

- Easy to install: They are typically self-tapping, which eliminates the need for pre-drilling.

- Available in various lengths and finishes: This allows for customization based on the specific needs of the project.

Disadvantages of Cabinet Screws:

- Cost: Cabinet screws are typically more expensive than wood screws or drywall screws.

- May require specialized tools: Some cabinet screws require a specific driver bit for proper installation.

Examples of Cabinet Screw Brands:

- GRK Fasteners: Offers a variety of cabinet screws with different lengths and finishes.

- Spax: Provides cabinet screws with a unique self-tapping design for easy installation.

- Simpson Strong-Tie: Produces cabinet screws specifically designed for attaching cabinet components.

Self-Tapping Screws

Self-tapping screws are designed to cut their own threads as they are driven into the material. This makes them ideal for use in applications where pre-drilling is not practical or desirable.

Advantages of Self-Tapping Screws:

- Easy to install: Self-tapping screws can be driven directly into wood without the need for pre-drilling.

- Versatile: They can be used in a variety of applications, including cabinet construction.

Disadvantages of Self-Tapping Screws:

- May not provide as strong a hold as wood screws: The thread depth of self-tapping screws may be shallower than wood screws, which can result in a weaker hold.

- Can damage the material: If the screw is not properly aligned, it can damage the wood as it is driven in.

Examples of Self-Tapping Screw Brands:

- GRK Fasteners: Offers a variety of self-tapping screws with different lengths and finishes.

- Spax: Provides self-tapping screws with a unique design for easy installation.

- Simpson Strong-Tie: Produces self-tapping screws specifically designed for cabinet construction.

Factors to Consider When Choosing Screws: Best Screws For Cabinet Face Frames

Choosing the right screws for your cabinet face frames is crucial for ensuring a strong, durable, and aesthetically pleasing finish. The right screws will hold the frame together securely, prevent splitting, and blend seamlessly with the overall design.

Material of the Cabinet Face Frame

The material of your cabinet face frame significantly influences the type of screws you should use. The hardness and density of the wood affect the holding power and risk of splitting.

- Plywood: Plywood is a versatile material that offers good strength and stability. It can be used for both traditional and modern cabinets. For plywood face frames, you can use screws that are slightly shorter than those used for solid wood, as the plywood layers provide extra support. This reduces the risk of splitting.

- Solid Wood: Solid wood, such as oak, maple, or cherry, is a classic choice for cabinet face frames. It is durable and can be stained or painted to match your desired aesthetic. For solid wood face frames, you will need screws that are long enough to provide adequate holding power but not so long that they risk splitting the wood.

Screw Length and Diameter

The length and diameter of the screw determine its holding power and the risk of splitting the wood.

- Screw Length: The length of the screw should be sufficient to penetrate the wood completely and engage with the backing material. However, a screw that is too long can cause splitting, especially in thin or delicate wood.

- Screw Diameter: A larger diameter screw offers greater holding power, but it also increases the risk of splitting the wood. For thin wood, it is best to use a screw with a smaller diameter.

Screw Finish

The finish of the screw is important for matching the cabinet hardware and preventing corrosion.

- Matching Hardware: Screws with a finish that matches the cabinet hardware will create a cohesive and polished look. For example, if your cabinet hardware is brass, use brass screws.

- Corrosion Resistance: Screws with a finish that resists corrosion will prevent rusting and discoloration, especially in humid environments. For example, stainless steel screws are an excellent choice for bathrooms and kitchens.

Screw Selection for Different Cabinet Styles

The style of your cabinet can influence the type of screws you choose.

- Traditional Cabinets: Traditional cabinets often feature a more ornate design with visible screws. You can use screws with a decorative finish, such as antique brass or nickel, to complement the style.

- Modern Cabinets: Modern cabinets tend to have a minimalist aesthetic with hidden screws. You can use screws with a simple, polished finish, such as stainless steel or chrome, to maintain a clean look.

- Rustic Cabinets: Rustic cabinets often feature a more natural look with exposed wood. You can use screws with a rustic finish, such as black oxide or bronze, to enhance the overall aesthetic.

Installation Techniques for Cabinet Face Frames

Installing cabinet face frames involves careful screw placement to ensure a secure and aesthetically pleasing finish. This section will explore the proper methods for pre-drilling and countersinking holes to prevent wood splitting and achieve a flush finish. We will also delve into the use of pilot holes and countersinking tools, providing a step-by-step guide for installing screws for cabinet face frames. Finally, we will share tips for avoiding common mistakes during screw installation.

Pre-Drilling and Countersinking

Pre-drilling and countersinking are crucial steps in installing screws for cabinet face frames. These techniques prevent wood splitting and ensure a flush finish.

Pre-Drilling

Pre-drilling involves creating a pilot hole slightly smaller than the screw diameter. This allows the screw to thread smoothly into the wood without splitting it.

- Use a drill bit that is slightly smaller than the diameter of the screw you will be using.

- Drill the hole to a depth that is slightly shallower than the length of the screw.

Countersinking

Countersinking involves creating a conical recess around the pilot hole to accommodate the screw head. This prevents the screw head from protruding above the surface of the wood.

- Use a countersinking tool that matches the size and shape of the screw head.

- Countersink the hole to a depth that is slightly deeper than the thickness of the screw head.

Using Pilot Holes and Countersinking Tools

Pilot holes and countersinking tools are essential for precise and damage-free screw installation.

Pilot Holes

Pilot holes guide the screw and prevent it from wandering. They are crucial for accurate placement and a clean finish.

- Pilot holes should be slightly smaller than the diameter of the screw.

- Use a drill bit that is sharp and of the appropriate size.

Countersinking Tools

Countersinking tools create a recess for the screw head, ensuring a flush finish.

- Countersinking tools come in various sizes and shapes to accommodate different screw head types.

- Select a countersinking tool that matches the size and shape of the screw head you are using.

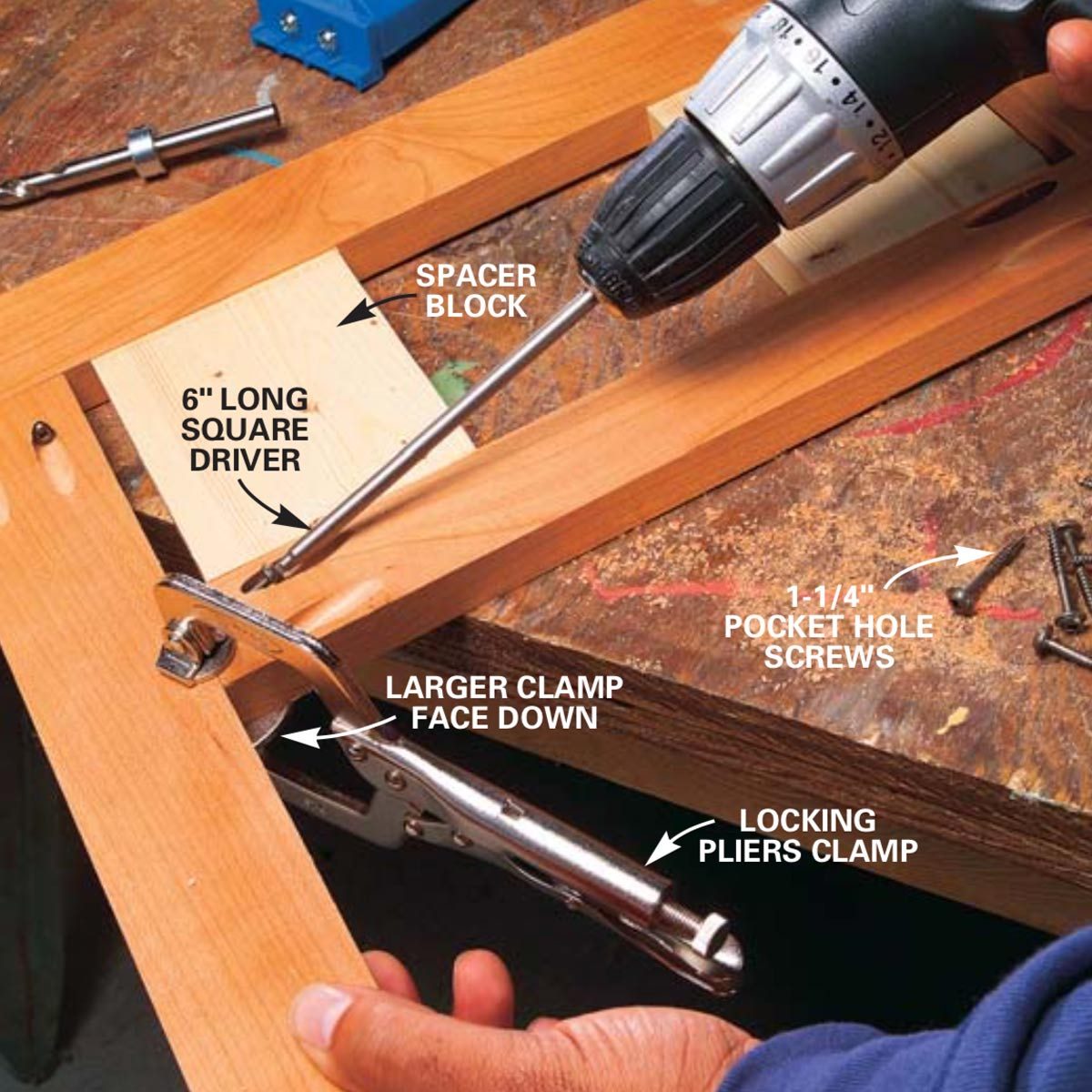

Step-by-Step Guide for Installing Screws for Cabinet Face Frames

Installing screws for cabinet face frames requires a systematic approach to ensure a secure and aesthetically pleasing result.

- Mark the screw locations: Use a pencil or marking tool to mark the exact locations where the screws will be installed.

- Pre-drill pilot holes: Use a drill bit slightly smaller than the screw diameter to create pilot holes at the marked locations. Drill to a depth slightly shallower than the length of the screw.

- Countersink the holes: Use a countersinking tool that matches the size and shape of the screw head to create a conical recess around the pilot hole.

- Install the screws: Drive the screws into the pre-drilled and countersunk holes. Use a screwdriver or drill driver with a suitable bit. Avoid overtightening the screws, as this can cause wood splitting or damage to the screw head.

- Check for flush finish: Ensure that the screw heads are flush with the surface of the wood. If necessary, use a countersinking tool to adjust the depth of the screw head.

Tips for Avoiding Common Mistakes During Screw Installation

Proper screw installation techniques are essential for a successful and durable cabinet face frame.

- Avoid overtightening screws: Overtightening can cause wood splitting or damage to the screw head. Tighten the screws until they are snug, but do not force them.

- Use the right screw length: Ensure that the screws are long enough to penetrate the wood securely, but not so long that they protrude through the other side.

- Use a pilot hole for every screw: Pilot holes prevent wood splitting and ensure a clean finish.

- Countersink the screw heads: Countersinking ensures a flush finish and prevents the screw heads from protruding above the surface of the wood.

- Use a countersinking tool that matches the screw head size: Using the wrong countersinking tool can result in a poor fit and an uneven finish.

Best screws for cabinet face frames – Choosing the right screws for cabinet face frames is crucial for a sturdy and professional finish. While selecting the perfect screws, you might also be thinking about sprucing up your bedroom with a fresh style. If you’re looking for inspiration, check out these bedroom styles for guys , which range from minimalist to gamer-themed.

Once you’ve settled on your ideal bedroom aesthetic, you can return to the task at hand – selecting the best screws for your cabinet face frames.

Choosing the right screws for cabinet face frames is crucial for a sturdy and long-lasting construction. While considering factors like wood type and thickness, it’s also important to think about the overall aesthetic. For example, a navy and turquoise bedroom might benefit from screws with a slightly more modern finish, like nickel or black oxide, to complement the cool tones of the space.

Ultimately, the best screws for your cabinet face frames will depend on your specific project needs and desired style.